Micro-Flute is making inroads in the folding carton world, offering additional options and capabilities for product manufactures and brand owners. According to AICC (Association of Independent Corrugated Converters) micro-flute packaging makes up 5-7% of total US corrugated shipments.

Micro-flute is a very thin corrugated board. It is made of a fluted corrugated sheet, the wavy part, with a liner board adhered to each side. Traditional folding carton material is typically made up of a single layer of cardboard of varying thickness. The three most common thicknesses of Micro-flute have letters associated with their names, E-flute, N-flute, and F-flute.

N-flute: The finest flute

N-flute is the finest flute specially engineered to allow for direct litho printing (sheet feeding). It consists of 3 layers of paper with an N-Flute profile. The composition of linerboard can be adapted to the needs. It could be for instance Coated SBS on Kraft, Kraft on Kraft, Coated SBS on Black or 100% recycled fiber… the combinations are endless.

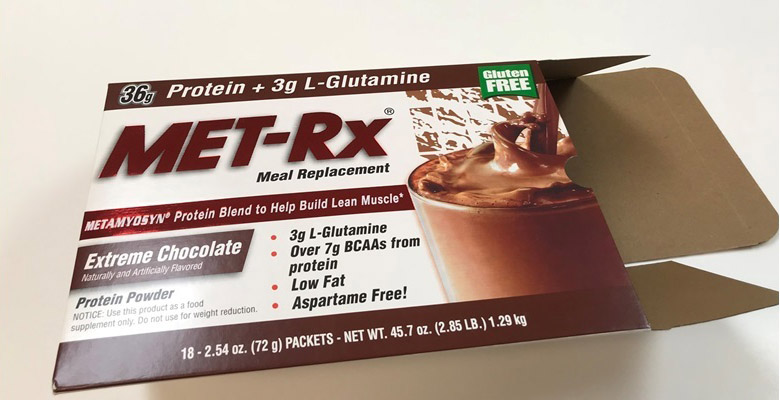

Ideally used as a packaging material in applications such as Retail Ready Packaging (RRP), POS display, Bag-in-Box, for Consumer Packaging (cosmetics, food and nutraceuticals), and E-Commerce markets.

N-flute vs. E-flute and Solid board

There is not a significant amount of difference between E-flute and N-flute. N-flute is about half as thick and E-flute and has about 35% more flutes per inch. N-flute is light in weight, offers exceptional protection and has a superior surface for printing. One of the key attributes of using N-flute is its cost-effectiveness since most packaging types are currently under cost-cutting pressure.

Advantages over solid board or thick cardboard material include the fact that less raw material is required to achieve a given level of stability. N-flute packaging also has better stacking and flexural strength and weighs less. Its superior insulating properties also make it ideal for deep-freeze fast-food packaging.

Short-grain material must be used for micro-flute printing. The flutes then lie in the direction of travel, offering greater stability. The blanket is the key parameter for micro-flute printing since it must be able to ensure good ink transfer even at low pressures. Therefore, inks that transfer well, even at the lowest of pressures, should be selected.

N-Flute Benefits

Micro-flute has all the benefits of a folding carton combined with the strength of corrugated. Micro-flute provides greater protection since corrugated structure of N-flute offers a stiffer and more rigid package. In terms of box performance, N-flute box offers superior compression strength in addition to greater bulge resistance. This means even greater product protection! Other key benefits are: short lead-times; size specific materials (bespoke sizes) and a wide range of liners combinations (kraft liner, white liner, metalized liner….) and low minimum order quantities.

The N-Flute converts into box with lower fiber content and with reduced box weight while maintaining good performance. Thereby, it not only creates a rigid box with less fiber content and less material volume, but also it is an environmentally friendly structure that is easily recyclable (minimize carbon foot print).

We can support customers on the E-commerce, food & nutraceutical and cosmetic markets. Let our insightful team help you find a dynamic packing solution with Micro-flute. Contact us (Pack@supremex.com) to discuss all your packaging needs!