The cosmetic and beauty industry is flourishing like never before, with countless new cosmetic products making it onto the retail shelves every year. With today’s consumers being increasingly savvy and demanding to know what is in the products they use, communicating all the necessary information while standing out on-shelf is more important for beauty brands than ever. Packaging is an important factor in consumers’ shopping experience. It’s the silent salesperson sitting next to the competition. It’s the first thing consumers see when approaching an item of interest, and it’s what they can physically touch upon further inspection.

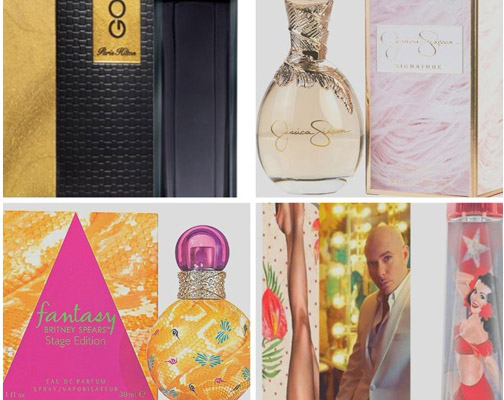

At SupremeX Folding Carton, our team of experienced press and finishing operators bring extensive knowledge and experience to cosmetic packaging carton. During the last 20 years we have proudly worked on exciting carton projects for many celebrities such as: Ariana Grande, Britney Spears, Nicki Minaj, Sean John, Pitbull, Justin Bieber and Jessica Simpson. We are also proud to serve major American fragrances brands, Like Elizabeth Arden, Juicy Couture and Ralph Lauren.

Many of these fragrance cartons use different finishes, press effects and present printing and finishing challenges. They use multiple printing techniques requiring strict color maintenance and extremely tight registration during converting.

1. Gloss UV Coating: This is one of the most popular coatings used in the industry. It provides a clear coating with a high gloss. An added benefit of this coating is that it can also serve as a protectant.

2. Spot UV Coating: it implies partial coverage, so it uses an extra plate or masked silkscreen on a separate printing pass and usually it is going to be a gloss “emboss” effect.

3. Reticulation Effect: This effect is achieved when a spot varnish and an overall UV coating is applied. When these two are mixed, there is a chemical reaction that results in a tactile and visual effect.

4. Raised UV Coating: A great way to add a tactile or more dramatic effect is by using a raised UV coating effect. Adding more coating volume brings more added dimension that can accentuate the art or graphic, as well as invite the consumer to engage and touch.

5. Pearlescent Coating: If a luxurious shimmer appearance is what you’re looking for, then a pearlescent coating is the way to go.

6. Glitter Coating: For a stark and bold look, glitter coatings are the way to go. Glitter coatings are made when large glitter particles (50-200 microns) are added into UV gloss coating. They also come in a wide assortment of colors.

7. Soft Touch Coating: creates a soft, velvety texture. It also makes the piece look softer than one with a high gloss or textured coatings.

8. Metallic Sheen Coating: Silver and gold sheen coatings give any carton a ritzy touch. If your budget doesn’t allow for foil stamping, metallic sheens are a great cost-effective alternative that delivers the same look and feel.

9. Grit Coating: This coating is known for their coarse and rugged tactile effect.

10. Embossing & Debossing: Raising and depressing aspects of your carton gives your customers a tactile experience.

11. Hot Foil Stamping: This effect is accomplished with a foil stamping machine that uses a metal plate that has been engraved with an image of the desired design required for the particular application.

12. Window Patch: this is a technique where a window film is added on a carton or any other product packaging serving a dual purpose – it teases the product by making some of it visible and can also it prevent food from coming into contact with the carton.

Partnering with an industry expert like SupremeX helps you create the desired effect for each folding carton project.

Take your complex fragrance and cosmetic carton projects to the next level with SupremeX Folding Carton Team. Our experienced and devoted team will make it happen. Contact us at Pack@SupremeX.com